Equipment Director Salary in the United States

Equipment Director Salary

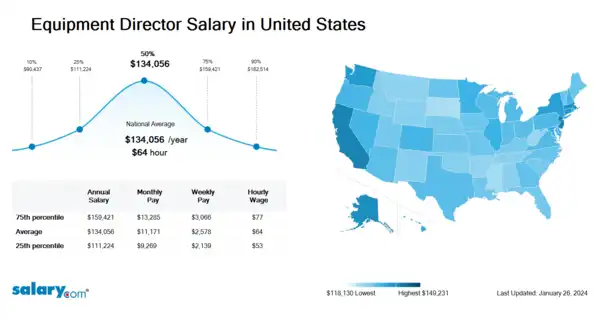

How much does an Equipment Director make in the United States? The average Equipment Director salary in the United States is $134,653 as of March 26, 2024, but the range typically falls between $111,721 and $160,137. Salary ranges can vary widely depending on many important factors, including education, certifications, additional skills, the number of years you have spent in your profession. With more online, real-time compensation data than any other website, Salary.com helps you determine your exact pay target.

| Percentile | Salary | Location | Last Updated |

| 10th Percentile Equipment Director Salary | $90,844 | US | March 26, 2024 |

| 25th Percentile Equipment Director Salary | $111,721 | US | March 26, 2024 |

| 50th Percentile Equipment Director Salary | $134,653 | US | March 26, 2024 |

| 75th Percentile Equipment Director Salary | $160,137 | US | March 26, 2024 |

| 90th Percentile Equipment Director Salary | $183,340 | US | March 26, 2024 |

Redline Equipment - Archbold, OH

Director Safety, Health Environmental and Security

Austin Powder - Beachwood, OH

the trak group - Cincinnati, OH

Telecom Central Office Equipment Installation Technician

Strategic Direct Solutions, LLC - Cleveland, OH

- View Hourly Wages

-

Select State

-

Select City

-

Choose Similar Job

-

Pick Related Category

- View Cost of Living in Major Cities

What skills does an Equipment Director need?

Each competency has five to ten behavioral assertions that can be observed, each with a corresponding performance level (from one to five) that is required for a particular job.

Customer Service: Customer service is the provision of service to customers before, during and after a purchase. The perception of success of such interactions is dependent on employees "who can adjust themselves to the personality of the guest". Customer service concerns the priority an organization assigns to customer service relative to components such as product innovation and pricing. In this sense, an organization that values good customer service may spend more money in training employees than the average organization or may proactively interview customers for feedback. From the point of view of an overall sales process engineering effort, customer service plays an important role in an organization's ability to generate income and revenue. From that perspective, customer service should be included as part of an overall approach to systematic improvement. One good customer service experience can change the entire perception a customer holds towards the organization.

High Volume Service: High-volume operations, also called flow operations, can be repetitive operations for discrete products like automobiles, appliances, or bread, or services like license renewals at the Division of Motor Vehicles.

Safety Standards: Safety standards are designed to ensure the safety of products, activities and processes, etc. They may be advisory or compulsory and are normally laid down by an advisory or regulatory body that may be either voluntary or statutory.

Job Description for Equipment Director

Equipment Director directs the management of company equipment including procurement activities, preventative maintenance, repair/replacement and safety assurance. Manages the records, licenses, inspections, warrantees, and service agreements for the organization's equipment and tools. Being an Equipment Director minimizes organizational cost through product standardization and tracking. Document and tracks equipment performance throughout the product lifetime. Additionally, Equipment Director requires a bachelor's degree. Typically reports to top management. The Equipment Director typically manages through subordinate managers and professionals in larger groups of moderate complexity. Provides input to strategic decisions that affect the functional area of responsibility. May give input into developing the budget. Capable of resolving escalated issues arising from operations and requiring coordination with other departments. To be an Equipment Director typically requires 3+ years of managerial experience. (Copyright 2024 Salary.com)... View full job description

See user submitted job responsibilities for Equipment Director.

Search Job Openings

Salary.com job board provides millions of Equipment Director information for you to search for. Click on search button below to see Equipment Director job openings or enter a new job title here.

What does an Equipment Director do?

Are you an HR manager or compensation specialist?

Salary.com's CompAnalyst platform offers:

- Detailed skills and competency reports for specific positions

- Job and employee pricing reports

- Compensation data tools, salary structures, surveys and benchmarks.

Equipment Director Pay Difference by Location

Equipment Director salary varies from city to city. Compared with national average salary of Equipment Director, the highest Equipment Director salary is in San Francisco, CA, where the Equipment Director salary is 25.0% above. The lowest Equipment Director salary is in Miami, FL, where the Equipment Director salary is 3.5% lower than national average salary.

| City, State | Compared to national average |

|---|---|

| City, State San Francisco, CA |

Compared to national average

|

| City, State Washington, DC |

Compared to national average

|

| City, State Miami, FL |

Compared to national average

|

| City, State Chicago, IL |

Compared to national average

|

| City, State Boston, MA |

Compared to national average

|

| City, State New York, NY |

Compared to national average

|

| City, State Dallas, TX |

Compared to national average

|

Similar Jobs to Equipment Director

| Job Title | Experience | EDUCATION | Salary Compared to This Job |

|---|---|---|---|

| Job Title Biomedical Equipment Services Director | Experience | EducationBachelors | Salary Compared to This Job |

| Job Title Dialysis Equipment Technician | Experience 3 - 5 | EducationAssociates | Salary Compared to This Job |

| Job Title Equipment Manager | Experience 5 + | EducationBachelors | Salary Compared to This Job |

| Job Title Estimating Director | Experience | EducationBachelors | Salary Compared to This Job |

| Job Title Heavy Equipment Operator I | Experience 0 - 1 | EducationHigh School | Salary Compared to This Job |

Level of Education for Equipment Director

Jobs with different levels of education may pay very differently. Check the Equipment Director salary of your education level.

Equipment Director Salary by Global Country

Equipment Director salary varies from country to country. There are several factors that mainly impact the Equipment Director salary, including cost of living, economic conditions, market rates and legal differences. Click below to Equipment Director salary of the other country.

Equipment Director Salary by State

Geographic variations impact Equipment Director salary levels, due to various factors, such as cost of living, industries, market demand and company budgets. Click below to see pay differences between states.

Browse All Materials Management Jobs by Salary Level

Browse Related Job Categories With Equipment Director

A job category is a classification or grouping of job positions that share similar characteristics, functions, or industries. Equipment Director salary varies from category to category. Click below to see Equipment Director salary in different categories.

Take just three simple steps below to generate your own personalized salary report

Understand the total compensation opportunity for an Equipment Director, base salary plus other pay elements

Average Base Salary

Core compensation

Average Total Cash Compensation

Includes base and annual incentives

View the Cost of Living in Major Cities

Skills associated with Equipment Director: Budget Administration, Equipment Maintenance

Salary estimation for Equipment Director at companies like : Ponce Pulmonary Group en, ladera holdings ii LLC, North Health Navigation LLC

Jobs with a similar salary range to Equipment Director : Chief Product Owner