Plant Operations Manager Salary in the United States

Plant Operations Manager Salary

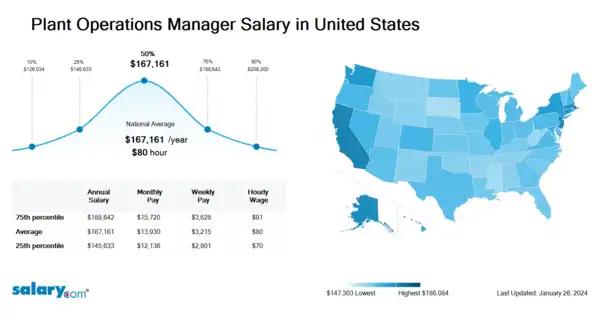

How much does a Plant Operations Manager make in the United States? The average Plant Operations Manager salary in the United States is $168,100 as of March 26, 2024, but the range typically falls between $146,454 and $189,704. Salary ranges can vary widely depending on many important factors, including education, certifications, additional skills, the number of years you have spent in your profession. With more online, real-time compensation data than any other website, Salary.com helps you determine your exact pay target.

| Percentile | Salary | Location | Last Updated |

| 10th Percentile Plant Operations Manager Salary | $126,747 | US | March 26, 2024 |

| 25th Percentile Plant Operations Manager Salary | $146,454 | US | March 26, 2024 |

| 50th Percentile Plant Operations Manager Salary | $168,100 | US | March 26, 2024 |

| 75th Percentile Plant Operations Manager Salary | $189,704 | US | March 26, 2024 |

| 90th Percentile Plant Operations Manager Salary | $209,374 | US | March 26, 2024 |

Ciresi & Morek - Akron, OH

Industrial Resource Group - Cincinnati, OH

Projekts Staffing and Consulting - Columbus, OH

CEO Inc. - Ironton, OH

- View Hourly Wages

-

Select State

-

Select City

-

Choose Similar Job

-

Pick Related Category

- View Cost of Living in Major Cities

What skills does a Plant Operations Manager need?

Each competency has five to ten behavioral assertions that can be observed, each with a corresponding performance level (from one to five) that is required for a particular job.

Leadership: Knowledge of and ability to employ effective strategies that motivate and guide other members within our business to achieve optimum results.

Laundry: Laundry refers to the washing of clothing and other textiles. Laundry processes are often done in a room reserved for that purpose; in an individual home this is referred to as a laundry room, Laundry in Australian English or utility room. An apartment building or student hall of residence may have a shared laundry facility such as a tvättstuga. A stand-alone business is referred to as a self-service laundry (launderette in British English or laundromat in American English). The material that is being washed, or has been laundered, is also generally referred to as laundry. Laundry has been part of history since humans began to wear clothes, so the methods by which different cultures have dealt with this universal human need are of interest to several branches of scholarship. Laundry work has traditionally been highly gendered, with the responsibility in most cultures falling to women (known as laundresses or washerwomen). The Industrial Revolution gradually led to mechanised solutions to laundry work, notably the washing machine and later the tumble dryer. Laundry, like cooking and child care, is done both at home and by commercial establishments outside the home.

Preventive Maintenance: Preventive maintenance is the act of performing regularly scheduled maintenance activities to help prevent unexpected failures in the future. Put simply, it's about fixing things before they break.

Job Description for Plant Operations Manager

Plant Operations Manager oversees the daily operational activities of a plant or production facility. Develops and manages production schedules to meet internal volume, cost, and quality goals. Being a Plant Operations Manager utilizes operational metrics to analyze productivity, identify issues, and set performance targets to achieve production goals. Implements plant safety and security inspections, auditing, and training procedures to meet OSHA and other required regulations. Additionally, Plant Operations Manager oversees staffing and development of all production supervisors and staff and facilitates labor relations. Typically requires a bachelor's degree in manufacturing engineering or equivalent. Typically reports to a director. The Plant Operations Manager typically manages through subordinate managers and professionals in larger groups of moderate complexity. Provides input to strategic decisions that affect the functional area of responsibility. May give input into developing the budget. To be a Plant Operations Manager typically requires 3+ years of managerial experience. Capable of resolving escalated issues arising from operations and requiring coordination with other departments. (Copyright 2024 Salary.com)... View full job description

See user submitted job responsibilities for Plant Operations Manager.

Search Job Openings

Salary.com job board provides millions of Plant Operations Manager information for you to search for. Click on search button below to see Plant Operations Manager job openings or enter a new job title here.

Career Path for Plant Operations Manager

A career path is a sequence of jobs that leads to your short- and long-term career goals. Some follow a linear career path within one field, while others change fields periodically to achieve career or personal goals.

For Plant Operations Manager, the first career path typically starts with a Manufacturing Director position, and then progresses to Top Division Manufacturing Executive.

Additionally, the second career path typically starts with a Plant Manager position, and then progresses to Plant General Manager.

What does a Plant Operations Manager do?

Are you an HR manager or compensation specialist?

Salary.com's CompAnalyst platform offers:

- Detailed skills and competency reports for specific positions

- Job and employee pricing reports

- Compensation data tools, salary structures, surveys and benchmarks.

Plant Operations Manager Pay Difference by Location

Plant Operations Manager salary varies from city to city. Compared with national average salary of Plant Operations Manager, the highest Plant Operations Manager salary is in San Francisco, CA, where the Plant Operations Manager salary is 25.0% above. The lowest Plant Operations Manager salary is in Miami, FL, where the Plant Operations Manager salary is 3.5% lower than national average salary.

| City, State | Compared to national average |

|---|---|

| City, State San Francisco, CA |

Compared to national average

|

| City, State Washington, DC |

Compared to national average

|

| City, State Miami, FL |

Compared to national average

|

| City, State Chicago, IL |

Compared to national average

|

| City, State Boston, MA |

Compared to national average

|

| City, State New York, NY |

Compared to national average

|

| City, State Dallas, TX |

Compared to national average

|

Similar Jobs to Plant Operations Manager

| Job Title | Experience | EDUCATION | Salary Compared to This Job |

|---|---|---|---|

| Job Title Chemical Plant Operations Manager | Experience 5 + | EducationBachelors | Salary Compared to This Job |

| Job Title Multi Plant General Manager | Experience | EducationBachelors | Salary Compared to This Job |

| Job Title Network Operations Manager | Experience 5 + | EducationBachelors | Salary Compared to This Job |

| Job Title Operations Manager | Experience 5 + | EducationBachelors | Salary Compared to This Job |

| Job Title Plant General Manager | Experience | EducationBachelors | Salary Compared to This Job |

Level of Education for Plant Operations Manager

Jobs with different levels of education may pay very differently. Check the Plant Operations Manager salary of your education level.

Plant Operations Manager Salary by Global Country

Plant Operations Manager salary varies from country to country. There are several factors that mainly impact the Plant Operations Manager salary, including cost of living, economic conditions, market rates and legal differences. Click below to Plant Operations Manager salary of the other country.

Plant Operations Manager Salary by State

Geographic variations impact Plant Operations Manager salary levels, due to various factors, such as cost of living, industries, market demand and company budgets. Click below to see pay differences between states.

Browse All Materials Management Jobs by Salary Level

Browse Related Job Categories With Plant Operations Manager

A job category is a classification or grouping of job positions that share similar characteristics, functions, or industries. Plant Operations Manager salary varies from category to category. Click below to see Plant Operations Manager salary in different categories.

Take just three simple steps below to generate your own personalized salary report

Understand the total compensation opportunity for a Plant Operations Manager, base salary plus other pay elements

Average Base Salary

Core compensation

Average Total Cash Compensation

Includes base and annual incentives

View the Cost of Living in Major Cities

Skills associated with Plant Operations Manager: Quality Management, Maintenance Planning, Global Operations, OSHA Standards & Compliance ...More

Recently searched related titles: Plant Production Manager

Jobs with a similar salary range to Plant Operations Manager : Plant Engineering Manager, Plant Operations Supervisor

Salary estimation for Plant Operations Manager at companies like : JCI National Accounts, America Homekey, Hoseah Hospice Palliative Care Inc

Jobs with a similar salary range to Plant Operations Manager : Plant Operations, Vice President Of Production