Extrusion Operator Salary in the United States

Extrusion Operator Salary

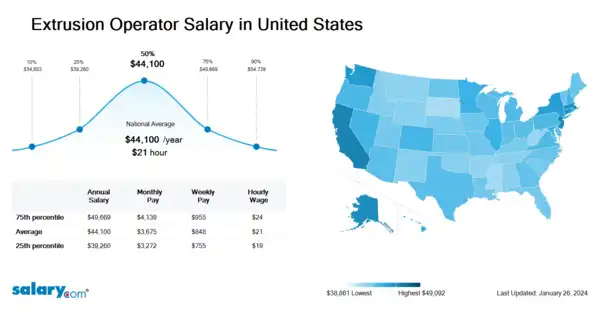

How much does an Extrusion Operator make in the United States? The average Extrusion Operator salary in the United States is $44,359 as of March 26, 2024, but the range typically falls between $39,490 and $49,957. Salary ranges can vary widely depending on many important factors, including education, certifications, additional skills, the number of years you have spent in your profession. With more online, real-time compensation data than any other website, Salary.com helps you determine your exact pay target.

| Percentile | Salary | Location | Last Updated |

| 10th Percentile Extrusion Operator Salary | $35,058 | US | March 26, 2024 |

| 25th Percentile Extrusion Operator Salary | $39,490 | US | March 26, 2024 |

| 50th Percentile Extrusion Operator Salary | $44,359 | US | March 26, 2024 |

| 75th Percentile Extrusion Operator Salary | $49,957 | US | March 26, 2024 |

| 90th Percentile Extrusion Operator Salary | $55,053 | US | March 26, 2024 |

Style Crest Inc. - Fremont, OH

Lead Flexible PVC Extrusions Machine Operator

DCA Construction Products - Garrettsville, OH

Kent Elastomer Products - Mogadore, OH

Extrusion Operator - Entry Level at $18/hour 6pm - 6am Monday through Thursday

Qualigence International - Painesville, OH

- View Hourly Wages

-

Select State

-

Select City

-

Choose Similar Job

-

Pick Related Category

- View Cost of Living in Major Cities

What skills does an Extrusion Operator need?

Each competency has five to ten behavioral assertions that can be observed, each with a corresponding performance level (from one to five) that is required for a particular job.

Troubleshooting: Troubleshooting is a form of problem solving, often applied to repair failed products or processes on a machine or a system. It is a logical, systematic search for the source of a problem in order to solve it, and make the product or process operational again. Troubleshooting is needed to identify the symptoms. Determining the most likely cause is a process of elimination—eliminating potential causes of a problem. Finally, troubleshooting requires confirmation that the solution restores the product or process to its working state. In general, troubleshooting is the identification or diagnosis of "trouble" in the management flow of a system caused by a failure of some kind. The problem is initially described as symptoms of malfunction, and troubleshooting is the process of determining and remedying the causes of these symptoms. A system can be described in terms of its expected, desired or intended behavior (usually, for artificial systems, its purpose). Events or inputs to the system are expected to generate specific results or outputs. (For example, selecting the "print" option from various computer applications is intended to result in a hardcopy emerging from some specific device). Any unexpected or undesirable behavior is a symptom. Troubleshooting is the process of isolating the specific cause or causes of the symptom. Frequently the symptom is a failure of the product or process to produce any results. (Nothing was printed, for example). Corrective action can then be taken to prevent further failures of a similar kind.

ISO: The International Organization for Standardization is an international standard development organization composed of representatives from the national standards organizations of member countries.

Preventative Maintenance: Developing and implementing maintenance strategies to increase equipment life expectancy and avoid unplanned downtime.

Job Description for Extrusion Operator

Extrusion Operator sets up and operates an extrusion machine in accordance with established procedures, guidelines, and customer requirements. Reads and interprets blueprints and diagrams to select, position, and secure machinery. Being an Extrusion Operator adjusts and cleans machines. Documents work performed as required. Additionally, Extrusion Operator may have to complete an apprenticeship and/or formal training in area of specialty. Requires a high school diploma or its equivalent. Typically reports to a supervisor/manager. The Extrusion Operator possesses a moderate understanding of general aspects of the job. Works under the close direction of senior personnel in the functional area. May require 0-1 year of general work experience. (Copyright 2024 Salary.com)... View full job description

See user submitted job responsibilities for Extrusion Operator.

Search Job Openings

Salary.com job board provides millions of Extrusion Operator information for you to search for. Click on search button below to see Extrusion Operator job openings or enter a new job title here.

Career Path for Extrusion Operator

A career path is a sequence of jobs that leads to your short- and long-term career goals. Some follow a linear career path within one field, while others change fields periodically to achieve career or personal goals.

For Extrusion Operator, the first career path typically progresses to Extrusion Operator, Sr..

The second career path typically starts with an Injection Molding Machine Operator II position, and then progresses to Injection Molding Machine Operator III.

The third career path typically starts with a Machine Operator II position, and then progresses to Machine Operator Supervisor.

Additionally, the fourth career path typically starts with a Machinist II position, and then progresses to Machine Shop Production Supervisor I.

What does an Extrusion Operator do?

Are you an HR manager or compensation specialist?

Salary.com's CompAnalyst platform offers:

- Detailed skills and competency reports for specific positions

- Job and employee pricing reports

- Compensation data tools, salary structures, surveys and benchmarks.

Extrusion Operator Pay Difference by Location

Extrusion Operator salary varies from city to city. Compared with national average salary of Extrusion Operator, the highest Extrusion Operator salary is in San Francisco, CA, where the Extrusion Operator salary is 25.0% above. The lowest Extrusion Operator salary is in Miami, FL, where the Extrusion Operator salary is 3.5% lower than national average salary.

| City, State | Compared to national average |

|---|---|

| City, State San Francisco, CA |

Compared to national average

|

| City, State Washington, DC |

Compared to national average

|

| City, State Miami, FL |

Compared to national average

|

| City, State Chicago, IL |

Compared to national average

|

| City, State Boston, MA |

Compared to national average

|

| City, State New York, NY |

Compared to national average

|

| City, State Dallas, TX |

Compared to national average

|

Similar Jobs to Extrusion Operator

| Job Title | Experience | EDUCATION | Salary Compared to This Job |

|---|---|---|---|

| Job Title Crane Operator, Sr. | Experience 3 - 5 | EducationHigh School | Salary Compared to This Job |

| Job Title Extrusion Operator, Sr. | Experience 1 - 3 | EducationHigh School | Salary Compared to This Job |

| Job Title Heavy Equipment Operator I | Experience 0 - 1 | EducationHigh School | Salary Compared to This Job |

| Job Title Heavy Equipment Operator II | Experience 1 - 3 | EducationHigh School | Salary Compared to This Job |

| Job Title Heavy Equipment Operator III | Experience 3 - 5 | EducationHigh School | Salary Compared to This Job |

Level of Education for Extrusion Operator

Jobs with different levels of education may pay very differently. Check the Extrusion Operator salary of your education level.

- Extrusion Operator Salaries with a High School Diploma or Technical Certificate

- Extrusion Operator Salaries with an Associate's Degree

- Extrusion Operator Salaries with a Bachelor's Degree

- Extrusion Operator Salaries with a Master's Degree or MBA

- Extrusion Operator Salaries with a JD, MD, PhD or Equivalent

Extrusion Operator Salary by Global Country

Extrusion Operator salary varies from country to country. There are several factors that mainly impact the Extrusion Operator salary, including cost of living, economic conditions, market rates and legal differences. Click below to Extrusion Operator salary of the other country.

Extrusion Operator Salary by State

Geographic variations impact Extrusion Operator salary levels, due to various factors, such as cost of living, industries, market demand and company budgets. Click below to see pay differences between states.

Browse All Skilled and Trades Jobs by Salary Level

Browse Related Job Categories With Extrusion Operator

A job category is a classification or grouping of job positions that share similar characteristics, functions, or industries. Extrusion Operator salary varies from category to category. Click below to see Extrusion Operator salary in different categories.

Take just three simple steps below to generate your own personalized salary report

Understand the total compensation opportunity for an Extrusion Operator, base salary plus other pay elements

Average Base Salary

Core compensation

Average Total Cash Compensation

Includes base and annual incentives

View the Cost of Living in Major Cities

Skills associated with Extrusion Operator: Machine Operation, Injection Molding, Machining, Milling ...More

Recently searched related titles: Extrusion Technician

Jobs with a similar salary range to Extrusion Operator : Extrusion Engineer, Extruder Operator

Salary estimation for Extrusion Operator at companies like : The Pacific Intermountain Parking and Transportation Association, Our Lord Elementary School, Pomona - PSC 144

Jobs with a similar salary range to Extrusion Operator : Plastic Extrusion Operator