Field Operator IV Salary in the United States

Field Operator IV Salary

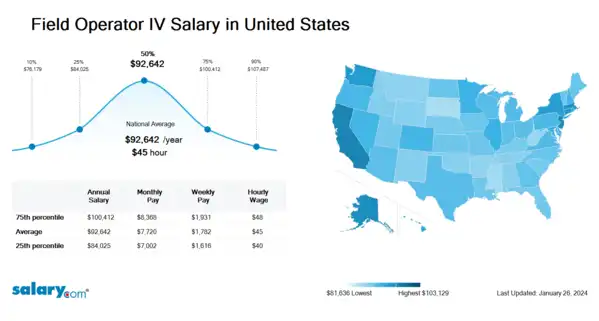

How much does a Field Operator IV make in the United States? The average Field Operator IV salary in the United States is $94,291 as of June 27, 2024, but the range typically falls between $85,665 and $102,167. Salary ranges can vary widely depending on many important factors, including education, certifications, additional skills, the number of years you have spent in your profession. With more online, real-time compensation data than any other website, Salary.com helps you determine your exact pay target.

| Percentile | Salary | Location | Last Updated |

| 10th Percentile Field Operator IV Salary | $77,811 | US | June 27, 2024 |

| 25th Percentile Field Operator IV Salary | $85,665 | US | June 27, 2024 |

| 50th Percentile Field Operator IV Salary | $94,291 | US | June 27, 2024 |

| 75th Percentile Field Operator IV Salary | $102,167 | US | June 27, 2024 |

| 90th Percentile Field Operator IV Salary | $109,337 | US | June 27, 2024 |

- View Hourly Wages

-

Select State

-

Select City

-

Choose Similar Job

-

Pick Related Category

- View Cost of Living in Major Cities

What skills does a Field Operator IV need?

Each competency has five to ten behavioral assertions that can be observed, each with a corresponding performance level (from one to five) that is required for a particular job.

Troubleshooting: Troubleshooting is a form of problem solving, often applied to repair failed products or processes on a machine or a system. It is a logical, systematic search for the source of a problem in order to solve it, and make the product or process operational again. Troubleshooting is needed to identify the symptoms. Determining the most likely cause is a process of elimination—eliminating potential causes of a problem. Finally, troubleshooting requires confirmation that the solution restores the product or process to its working state. In general, troubleshooting is the identification or diagnosis of "trouble" in the management flow of a system caused by a failure of some kind. The problem is initially described as symptoms of malfunction, and troubleshooting is the process of determining and remedying the causes of these symptoms. A system can be described in terms of its expected, desired or intended behavior (usually, for artificial systems, its purpose). Events or inputs to the system are expected to generate specific results or outputs. (For example, selecting the "print" option from various computer applications is intended to result in a hardcopy emerging from some specific device). Any unexpected or undesirable behavior is a symptom. Troubleshooting is the process of isolating the specific cause or causes of the symptom. Frequently the symptom is a failure of the product or process to produce any results. (Nothing was printed, for example). Corrective action can then be taken to prevent further failures of a similar kind.

Linux: Managing a system's hardware and resources using a Unix-like open-source operating system.

Material Handling: Material handling involves short-distance movement within the confines of a building or between a building and a transportation vehicle. It uses a wide range of manual, semi-automated, and automated equipment and includes consideration of the protection, storage, and control of materials throughout their manufacturing, warehousing, distribution, consumption, and disposal. Material handling can be used to create time and place utility through the handling, storage, and control of material, as distinct from manufacturing, which creates form utility by changing the shape, form, and makeup of material.

What Should I Pay?

Job Description for Field Operator IV

Field Operator IV sets up and operates a variety of oil, gas, or mining machines and equipment on designated sites. Reads and interprets blueprints and diagrams to select, operate, and properly secure machinery. Being a Field Operator IV maintains equipment and troubleshoots technical issues as necessary. Routinely monitors and tests equipment for quality and safety in accordance with established procedures, guidelines, and regulations. Additionally, Field Operator IV requires a high school diploma. Typically reports to a supervisor. The Field Operator IV independently performs a wide range of complex duties under general guidance from supervisors. Has gained full proficiency in a broad range of activities related to the job. To be a Field Operator IV typically requires 5-7 years of related experience. (Copyright 2024 Salary.com)... View full job description

See user submitted job responsibilities for Field Operator IV.

Search Job Openings

Salary.com job board provides millions of Field Operator IV information for you to search for. Click on search button below to see Field Operator IV job openings or enter a new job title here.

Career Path for Field Operator IV

A career path is a sequence of jobs that leads to your short- and long-term career goals. Some follow a linear career path within one field, while others change fields periodically to achieve career or personal goals.

For Field Operator IV, the first career path typically starts with a Field Service Technician V position, and then Field Service Supervisor.

The second career path typically progresses to Power Systems Rental Operations Manager.

Additionally, the third career path typically starts with a Field Operations Supervisor position, and then progresses to Field Operations Supervisor, Sr..

What does a Field Operator IV do?

Are you an HR manager or compensation specialist?

Salary.com's CompAnalyst platform offers:

- Detailed skills and competency reports for specific positions

- Job and employee pricing reports

- Compensation data tools, salary structures, surveys and benchmarks.

Field Operator IV Pay Difference by Location

Field Operator IV salary varies from city to city. Compared with national average salary of Field Operator IV, the highest Field Operator IV salary is in San Francisco, CA, where the Field Operator IV salary is 25.0% above. The lowest Field Operator IV salary is in Miami, FL, where the Field Operator IV salary is 3.5% lower than national average salary.

| City, State | Compared to national average |

|---|---|

| City, State San Francisco, CA |

Compared to national average

|

| City, State Washington, DC |

Compared to national average

|

| City, State Miami, FL |

Compared to national average

|

| City, State Chicago, IL |

Compared to national average

|

| City, State Boston, MA |

Compared to national average

|

| City, State New York, NY |

Compared to national average

|

| City, State Dallas, TX |

Compared to national average

|

Similar Jobs to Field Operator IV

| Job Title | Experience | EDUCATION | Salary Compared to This Job |

|---|---|---|---|

| Job Title Field Service Director | Experience | EducationBachelors | Salary Compared to This Job |

| Job Title Field Service Engineer IV | Experience 7 + | EducationBachelors | Salary Compared to This Job |

| Job Title Field Service Manager | Experience 5 + | EducationBachelors | Salary Compared to This Job |

| Job Title Field Service Supervisor | Experience 3 + | EducationBachelors | Salary Compared to This Job |

| Job Title Field Service Technician I | Experience 0 - 1 | EducationHigh School | Salary Compared to This Job |

Level of Education for Field Operator IV

Jobs with different levels of education may pay very differently. Check the Field Operator IV salary of your education level.

- Field Operator IV Salaries with a High School Diploma or Technical Certificate

- Field Operator IV Salaries with an Associate's Degree

- Field Operator IV Salaries with a Bachelor's Degree

- Field Operator IV Salaries with a Master's Degree or MBA

- Field Operator IV Salaries with a JD, MD, PhD or Equivalent

Field Operator IV Salary by Global Country

Field Operator IV salary varies from country to country. There are several factors that mainly impact the Field Operator IV salary, including cost of living, economic conditions, market rates and legal differences. Click below to Field Operator IV salary of the other country.

Field Operator IV Salary by State

Geographic variations impact Field Operator IV salary levels, due to various factors, such as cost of living, industries, market demand and company budgets. Click below to see pay differences between states.

Browse All Skilled and Trades Jobs by Salary Level

Browse Related Job Categories With Field Operator IV

A job category is a classification or grouping of job positions that share similar characteristics, functions, or industries. Field Operator IV salary varies from category to category. Click below to see Field Operator IV salary in different categories.

Take just three simple steps below to generate your own personalized salary report

Understand the total compensation opportunity for a Field Operator IV, base salary plus other pay elements

Average Base Salary

Core compensation

Average Total Cash Compensation

Includes base and annual incentives

View the Cost of Living in Major Cities

Skills associated with Field Operator IV: Service Delivery, Field Service, Technical Troubleshooting, Technical Services ...More

Jobs with a similar salary range to Field Operator IV : Political Affairs Officer, Operations Specialist, Field Operator

Salary estimation for Field Operator IV at companies like : Kennedy-curry Middle School, Mt Clemens High School, Unit 104 LLC