Packaging Engineer III Salary in the United States

Packaging Engineer III Salary

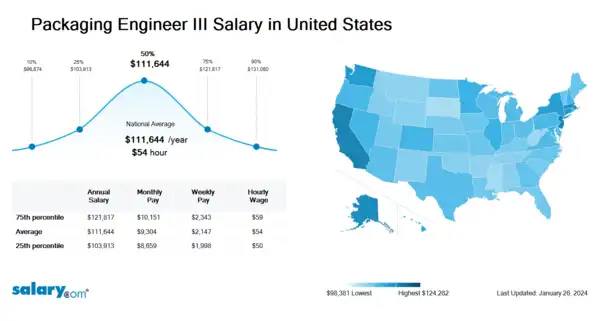

How much does a Packaging Engineer III make in the United States? The average Packaging Engineer III salary in the United States is $112,216 as of March 26, 2024, but the range typically falls between $104,444 and $122,445. Salary ranges can vary widely depending on many important factors, including education, certifications, additional skills, the number of years you have spent in your profession. With more online, real-time compensation data than any other website, Salary.com helps you determine your exact pay target.

| Percentile | Salary | Location | Last Updated |

| 10th Percentile Packaging Engineer III Salary | $97,368 | US | March 26, 2024 |

| 25th Percentile Packaging Engineer III Salary | $104,444 | US | March 26, 2024 |

| 50th Percentile Packaging Engineer III Salary | $112,216 | US | March 26, 2024 |

| 75th Percentile Packaging Engineer III Salary | $122,445 | US | March 26, 2024 |

| 90th Percentile Packaging Engineer III Salary | $131,758 | US | March 26, 2024 |

Civil Engineer 3 - 5 years w/PE

INTEGRITY FEDERAL SERVICES, INC. - Beachwood, OH

Eliassen Group - Cincinnati, OH

Pexco - Cincinnati, OH

Sale Engineer - Smart Packaging

Grantek Systems Integration - Cleveland, OH

- View Hourly Wages

-

Select State

-

Select City

-

Choose Similar Job

-

Pick Related Category

- View Cost of Living in Major Cities

What skills does a Packaging Engineer III need?

Each competency has five to ten behavioral assertions that can be observed, each with a corresponding performance level (from one to five) that is required for a particular job.

Planning: An act or process of making or carrying out plans. Establishment of goals, policies, and procedures for a social or economic unit city planning business planning.

Housekeeping: Housekeeping department is keeping the venue clean and sanitary as part of customer service. Cleaners vacuum rugs and furniture in hallways, rooms and public areas. They collect trash and empty wastebaskets, change the sheets and make the beds.

Continuous Improvement: A continual improvement process, also often called a continuous improvement process (abbreviated as CIP or CI), is an ongoing effort to improve products, services, or processes. These efforts can seek "incremental" improvement over time or "breakthrough" improvement all at once. Delivery (customer valued) processes are constantly evaluated and improved in the light of their efficiency, effectiveness and flexibility. Some see CIPs as a meta-process for most management systems (such as business process management, quality management, project management, and program management). W. Edwards Deming, a pioneer of the field, saw it as part of the 'system' whereby feedback from the process and customer were evaluated against organisational goals. The fact that it can be called a management process does not mean that it needs to be executed by 'management'; but rather merely that it makes decisions about the implementation of the delivery process and the design of the delivery process itself.

Job Description for Packaging Engineer III

Packaging Engineer III designs product packaging to ensure product integrity and appeal under varying shipping and display conditions. Tests, analyzes, and selects materials for packaging based on durability and cost effectiveness. Being a Packaging Engineer III evaluates the effectiveness of new package designs and ensures compliance with all requirements and regulations. Typically requires a bachelor's degree. Additionally, Packaging Engineer III typically reports to a manager or head of unit/department. The Packaging Engineer III contributes to moderately complex aspects of a project. Work is generally independent and collaborative in nature. To be a Packaging Engineer III typically requires 4 to 7 years of related experience. (Copyright 2024 Salary.com)... View full job description

See user submitted job responsibilities for Packaging Engineer III.

Search Job Openings

Salary.com job board provides millions of Packaging Engineer III information for you to search for. Click on search button below to see Packaging Engineer III job openings or enter a new job title here.

Career Path for Packaging Engineer III

A career path is a sequence of jobs that leads to your short- and long-term career goals. Some follow a linear career path within one field, while others change fields periodically to achieve career or personal goals.

For Packaging Engineer III, the upper level is Packaging Engineer IV and then progresses to Packaging Engineer V.

What does a Packaging Engineer III do?

Are you an HR manager or compensation specialist?

Salary.com's CompAnalyst platform offers:

- Detailed skills and competency reports for specific positions

- Job and employee pricing reports

- Compensation data tools, salary structures, surveys and benchmarks.

Packaging Engineer III Pay Difference by Location

Packaging Engineer III salary varies from city to city. Compared with national average salary of Packaging Engineer III, the highest Packaging Engineer III salary is in San Francisco, CA, where the Packaging Engineer III salary is 25.0% above. The lowest Packaging Engineer III salary is in Miami, FL, where the Packaging Engineer III salary is 3.5% lower than national average salary.

| City, State | Compared to national average |

|---|---|

| City, State San Francisco, CA |

Compared to national average

|

| City, State Washington, DC |

Compared to national average

|

| City, State Miami, FL |

Compared to national average

|

| City, State Chicago, IL |

Compared to national average

|

| City, State Boston, MA |

Compared to national average

|

| City, State New York, NY |

Compared to national average

|

| City, State Dallas, TX |

Compared to national average

|

Similar Jobs to Packaging Engineer III

| Job Title | Experience | EDUCATION | Salary Compared to This Job |

|---|---|---|---|

| Job Title DevOps Engineer III | Experience 4 - 7 | EducationBachelors | Salary Compared to This Job |

| Job Title Engineer III | Experience 4 - 7 | EducationBachelors | Salary Compared to This Job |

| Job Title Packaging Engineer I | Experience 0 - 2 | EducationBachelors | Salary Compared to This Job |

| Job Title Packaging Engineer II | Experience 2 - 4 | EducationBachelors | Salary Compared to This Job |

| Job Title Packaging Engineer IV | Experience 7 + | EducationBachelors | Salary Compared to This Job |

Level of Education for Packaging Engineer III

Jobs with different levels of education may pay very differently. Check the Packaging Engineer III salary of your education level.

- Packaging Engineer III Salaries with a High School Diploma or Technical Certificate

- Packaging Engineer III Salaries with an Associate's Degree

- Packaging Engineer III Salaries with a Bachelor's Degree

- Packaging Engineer III Salaries with a Master's Degree or MBA

- Packaging Engineer III Salaries with a JD, MD, PhD or Equivalent

Packaging Engineer III Salary by Global Country

Packaging Engineer III salary varies from country to country. There are several factors that mainly impact the Packaging Engineer III salary, including cost of living, economic conditions, market rates and legal differences. Click below to Packaging Engineer III salary of the other country.

Packaging Engineer III Salary by State

Geographic variations impact Packaging Engineer III salary levels, due to various factors, such as cost of living, industries, market demand and company budgets. Click below to see pay differences between states.

Browse All Engineering Jobs by Salary Level

Browse Related Job Categories With Packaging Engineer III

A job category is a classification or grouping of job positions that share similar characteristics, functions, or industries. Packaging Engineer III salary varies from category to category. Click below to see Packaging Engineer III salary in different categories.

Take just three simple steps below to generate your own personalized salary report

Understand the total compensation opportunity for a Packaging Engineer III, base salary plus other pay elements

Average Base Salary

Core compensation

Average Total Cash Compensation

Includes base and annual incentives

View the Cost of Living in Major Cities

Skills associated with Packaging Engineer III: Reliability Analysis, Design Review, Packaging Engineering, Packaging Design ...More

Recently searched related titles: Packaging Graphic Designer

Jobs with a similar salary range to Packaging Engineer III : Packaging Engineer

Salary estimation for Packaging Engineer III at companies like : Coon Memorial Hospital LLC, Duval County Council of PTAs, Mercedes-benz of Bourbonnais

Jobs with a similar salary range to Packaging Engineer III : Senior Packaging Designer