Packaging Manager Salary in the United States

Packaging Manager Salary

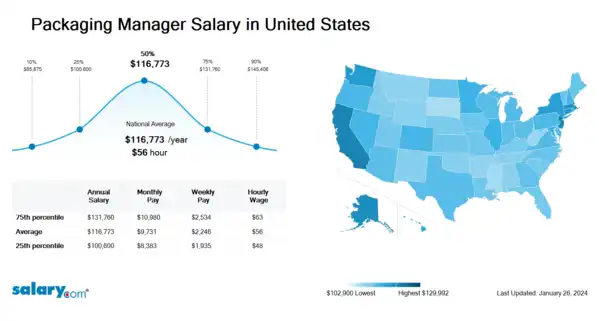

How much does a Packaging Manager make in the United States? The average Packaging Manager salary in the United States is $117,701 as of April 24, 2024, but the range typically falls between $101,397 and $132,811. Salary ranges can vary widely depending on many important factors, including education, certifications, additional skills, the number of years you have spent in your profession. With more online, real-time compensation data than any other website, Salary.com helps you determine your exact pay target.

| Percentile | Salary | Location | Last Updated |

| 10th Percentile Packaging Manager Salary | $86,553 | US | April 24, 2024 |

| 25th Percentile Packaging Manager Salary | $101,397 | US | April 24, 2024 |

| 50th Percentile Packaging Manager Salary | $117,701 | US | April 24, 2024 |

| 75th Percentile Packaging Manager Salary | $132,811 | US | April 24, 2024 |

| 90th Percentile Packaging Manager Salary | $146,567 | US | April 24, 2024 |

- View Hourly Wages

-

Select State

-

Select City

-

Choose Similar Job

-

Pick Related Category

- View Cost of Living in Major Cities

What skills does a Packaging Manager need?

Each competency has five to ten behavioral assertions that can be observed, each with a corresponding performance level (from one to five) that is required for a particular job.

Leadership: Knowledge of and ability to employ effective strategies that motivate and guide other members within our business to achieve optimum results.

Inventory Control: Inventory control or stock control can be broadly defined as "the activity of checking a shop’s stock." However, a more focused definition takes into account the more science-based, methodical practice of not only verifying a business' inventory but also focusing on the many related facets of inventory management (such as forecasting future demand) "within an organisation to meet the demand placed upon that business economically." Other facets of inventory control include supply chain management, production control, financial flexibility, and customer satisfaction. At the root of inventory control, however, is the inventory control problem, which involves determining when to order, how much to order, and the logistics (where) of those decisions. An extension of inventory control is the inventory control system. This may come in the form of a technological system and its programmed software used for managing various aspects of inventory problems , or it may refer to a methodology (which may include the use of technological barriers) for handling loss prevention in a business.

KPI: KPI stands for key performance indicator, a quantifiable measure of performance over time for a specific objective.

Job Description for Packaging Manager

Packaging Manager manages and oversees the packaging staff on designated shift to achieve operational objectives. Observes, analyzes, and researches packaging line operation to develop and implement scientific and efficient process. Being a Packaging Manager implements quality control check to ensure the packaging meets environment, health, and safety regulations. Provides staff with directions on materials and equipment for each package. Additionally, Packaging Manager may require a bachelor's degree. Typically reports to a head of a unit/department. The Packaging Manager manages subordinate staff in the day-to-day performance of their jobs. True first level manager. Ensures that project/department milestones/goals are met and adhering to approved budgets. Has full authority for personnel actions. Extensive knowledge of department processes. To be a Packaging Manager typically requires 5 years experience in the related area as an individual contributor. 1 to 3 years supervisory experience may be required. (Copyright 2024 Salary.com)... View full job description

See user submitted job responsibilities for Packaging Manager.

Search Job Openings

Salary.com job board provides millions of Packaging Manager information for you to search for. Click on search button below to see Packaging Manager job openings or enter a new job title here.

What does a Packaging Manager do?

Are you an HR manager or compensation specialist?

Salary.com's CompAnalyst platform offers:

- Detailed skills and competency reports for specific positions

- Job and employee pricing reports

- Compensation data tools, salary structures, surveys and benchmarks.

Packaging Manager Pay Difference by Location

Packaging Manager salary varies from city to city. Compared with national average salary of Packaging Manager, the highest Packaging Manager salary is in San Francisco, CA, where the Packaging Manager salary is 25.0% above. The lowest Packaging Manager salary is in Miami, FL, where the Packaging Manager salary is 3.5% lower than national average salary.

| City, State | Compared to national average |

|---|---|

| City, State San Francisco, CA |

Compared to national average

|

| City, State Washington, DC |

Compared to national average

|

| City, State Miami, FL |

Compared to national average

|

| City, State Chicago, IL |

Compared to national average

|

| City, State Boston, MA |

Compared to national average

|

| City, State New York, NY |

Compared to national average

|

| City, State Dallas, TX |

Compared to national average

|

Similar Jobs to Packaging Manager

| Job Title | Experience | EDUCATION | Salary Compared to This Job |

|---|---|---|---|

| Job Title Packaging Engineer I | Experience 0 - 2 | EducationBachelors | Salary Compared to This Job |

| Job Title Packaging Engineer II | Experience 2 - 4 | EducationBachelors | Salary Compared to This Job |

| Job Title Packaging Engineer III | Experience 4 - 7 | EducationBachelors | Salary Compared to This Job |

| Job Title Packaging Engineer IV | Experience 7 + | EducationBachelors | Salary Compared to This Job |

| Job Title Packaging Engineering Manager | Experience 5 + | EducationBachelors | Salary Compared to This Job |

Level of Education for Packaging Manager

Jobs with different levels of education may pay very differently. Check the Packaging Manager salary of your education level.

- Packaging Manager Salaries with a High School Diploma or Technical Certificate

- Packaging Manager Salaries with an Associate's Degree

- Packaging Manager Salaries with a Bachelor's Degree

- Packaging Manager Salaries with a Master's Degree or MBA

- Packaging Manager Salaries with a JD, MD, PhD or Equivalent

Packaging Manager Salary by State

Geographic variations impact Packaging Manager salary levels, due to various factors, such as cost of living, industries, market demand and company budgets. Click below to see pay differences between states.

Browse All Manufacturing Jobs by Salary Level

Browse Related Job Categories With Packaging Manager

A job category is a classification or grouping of job positions that share similar characteristics, functions, or industries. Packaging Manager salary varies from category to category. Click below to see Packaging Manager salary in different categories.

Take just three simple steps below to generate your own personalized salary report

Understand the total compensation opportunity for a Packaging Manager, base salary plus other pay elements

Average Base Salary

Core compensation

Average Total Cash Compensation

Includes base and annual incentives

View the Cost of Living in Major Cities

Skills associated with Packaging Manager: Machine Operation, Numerical Control, Precision Measurement, Injection Molding ...More

Jobs with a similar salary range to Packaging Manager : Packaging Project Manager, Package Manager

Salary estimation for Packaging Manager at companies like : Salesforce AR Operations, The Assn of Organ Procurement Organization, Foothills Rural Telephone Cooperative Corp Inc