Central Supply Supervisor Salary in the United States

Central Supply Supervisor Salary

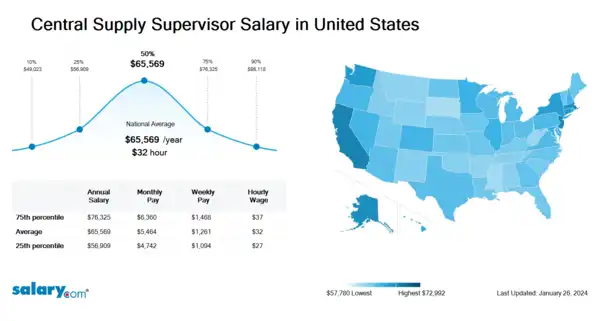

How much does a Central Supply Supervisor make in the United States? The average Central Supply Supervisor salary in the United States is $65,824 as of April 24, 2024, but the range typically falls between $57,129 and $76,621. Salary ranges can vary widely depending on many important factors, including education, certifications, additional skills, the number of years you have spent in your profession. With more online, real-time compensation data than any other website, Salary.com helps you determine your exact pay target.

| Percentile | Salary | Location | Last Updated |

| 10th Percentile Central Supply Supervisor Salary | $49,212 | US | April 24, 2024 |

| 25th Percentile Central Supply Supervisor Salary | $57,129 | US | April 24, 2024 |

| 50th Percentile Central Supply Supervisor Salary | $65,824 | US | April 24, 2024 |

| 75th Percentile Central Supply Supervisor Salary | $76,621 | US | April 24, 2024 |

| 90th Percentile Central Supply Supervisor Salary | $86,451 | US | April 24, 2024 |

- View Hourly Wages

-

Select State

-

Select City

-

Choose Similar Job

-

Pick Related Category

- View Cost of Living in Major Cities

What skills does a Central Supply Supervisor need?

Each competency has five to ten behavioral assertions that can be observed, each with a corresponding performance level (from one to five) that is required for a particular job.

Planning: An act or process of making or carrying out plans. Establishment of goals, policies, and procedures for a social or economic unit city planning business planning.

Logistics: In a general business sense, logistics is the management of the flow of things between the point of origin and the point of consumption to meet the requirements of customers or corporations.

Warehouse Operations: In its simplest form, “warehousing” is the storage of goods until they are needed. The goal of warehouse operations is to satisfy customers' needs and requirements while utilizing space, equipment, and labor effectively.

Job Description for Central Supply Supervisor

Central Supply Supervisor supervises employees responsible for either all central supply functions or one specific function such as sterilization, equipment distribution, or linen supply. Assists employees in day-to-day tasks and ensures hospital procedures are followed and standards are met. Being a Central Supply Supervisor may require a bachelor's degree. Typically reports to a manager. The Central Supply Supervisor supervises a small group of para-professional staff in an organization characterized by highly transactional or repetitive processes. Contributes to the development of processes and procedures. To be a Central Supply Supervisor typically requires 3 years experience in the related area as an individual contributor. Thorough knowledge of functional area under supervision. (Copyright 2024 Salary.com)... View full job description

See user submitted job responsibilities for Central Supply Supervisor.

Search Job Openings

Salary.com job board provides millions of Central Supply Supervisor information for you to search for. Click on search button below to see Central Supply Supervisor job openings or enter a new job title here.

Career Path for Central Supply Supervisor

A career path is a sequence of jobs that leads to your short- and long-term career goals. Some follow a linear career path within one field, while others change fields periodically to achieve career or personal goals.

For Central Supply Supervisor, the first career path typically progresses to Central Supply Manager.

What does a Central Supply Supervisor do?

Are you an HR manager or compensation specialist?

Salary.com's CompAnalyst platform offers:

- Detailed skills and competency reports for specific positions

- Job and employee pricing reports

- Compensation data tools, salary structures, surveys and benchmarks.

Central Supply Supervisor Pay Difference by Location

Central Supply Supervisor salary varies from city to city. Compared with national average salary of Central Supply Supervisor, the highest Central Supply Supervisor salary is in San Francisco, CA, where the Central Supply Supervisor salary is 25.0% above. The lowest Central Supply Supervisor salary is in Miami, FL, where the Central Supply Supervisor salary is 3.5% lower than national average salary.

| City, State | Compared to national average |

|---|---|

| City, State San Francisco, CA |

Compared to national average

|

| City, State Washington, DC |

Compared to national average

|

| City, State Miami, FL |

Compared to national average

|

| City, State Chicago, IL |

Compared to national average

|

| City, State Boston, MA |

Compared to national average

|

| City, State New York, NY |

Compared to national average

|

| City, State Dallas, TX |

Compared to national average

|

Similar Jobs to Central Supply Supervisor

| Job Title | Experience | EDUCATION | Salary Compared to This Job |

|---|---|---|---|

| Job Title Central Supply Manager | Experience | EducationBachelors | Salary Compared to This Job |

| Job Title Supply Chain Analyst I | Experience 0 - 2 | EducationBachelors | Salary Compared to This Job |

| Job Title Supply Chain Analyst II | Experience 2 - 4 | EducationBachelors | Salary Compared to This Job |

| Job Title Supply Chain Analyst III | Experience 4 - 7 | EducationBachelors | Salary Compared to This Job |

| Job Title Supply Chain Analyst IV | Experience 7 + | EducationBachelors | Salary Compared to This Job |

Level of Education for Central Supply Supervisor

Jobs with different levels of education may pay very differently. Check the Central Supply Supervisor salary of your education level.

Central Supply Supervisor Salary by State

Geographic variations impact Central Supply Supervisor salary levels, due to various factors, such as cost of living, industries, market demand and company budgets. Click below to see pay differences between states.

Browse All Healthcare - Administrative Jobs by Salary Level

Browse Related Job Categories With Central Supply Supervisor

A job category is a classification or grouping of job positions that share similar characteristics, functions, or industries. Central Supply Supervisor salary varies from category to category. Click below to see Central Supply Supervisor salary in different categories.

Take just three simple steps below to generate your own personalized salary report

Understand the total compensation opportunity for a Central Supply Supervisor, base salary plus other pay elements

Average Base Salary

Core compensation

Average Total Cash Compensation

Includes base and annual incentives

View the Cost of Living in Major Cities

Skills associated with Central Supply Supervisor: Medical Devices and Tools, Inspection, Standard Operating Procedures (SOP), Cleaning/Sanitation ...More

Recently searched related titles: Sterile Processing Supervisor, Spd Manager

Jobs with a similar salary range to Central Supply Supervisor : Global Supply Planner, Supply Supervisor

Salary estimation for Central Supply Supervisor at companies like : Digital Globe, mdSarosh Zafar, MD, Yuasa International - Ohio Technical Center